Hi!

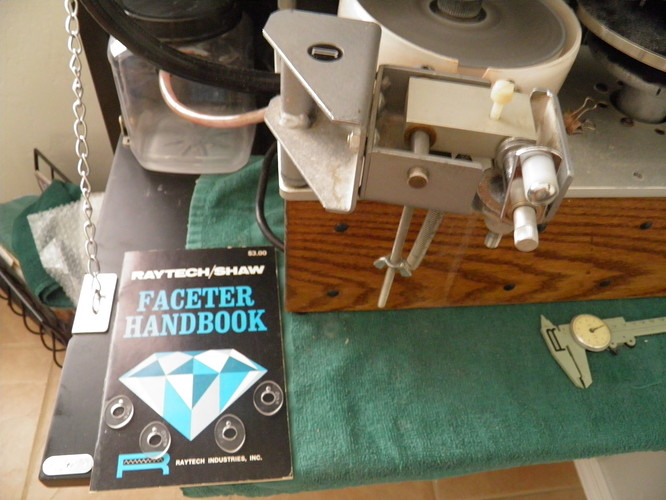

I started shaping semiprecious stones with sandpaper a few years ago (after a lifetime loving minerals in all forms), and now I’m obsessed with lapidary. I graduated to a small bench grinder that has allowed me to trim, shape, and polish rough into (mostly sphere-based) freeform shapes and practice cutting traditional cabochon designs. After a bit of research I resolved to buy a Raytech Shaw faceting machine, saved for over a year, and placed an order.

While waiting for the unit to arrive I want to gather as much knowledge as possible in order to hit the ground running, ergo this thread. I have seen a few videos on YouTube that mostly feature the Sri Lankan machines, but not much content geared specifically towards the Raytech.

TLDR;

- Are there any Raytech-specific resources out there?

- How different is the Raytech from other handpiece designs?

- Does anyone have any workshop design tips for the Raytech? Specifically ergonomics, as the way you sit at this machine appears to be different from others (but it’s hard to tell due to the dearth of Raytech-specific information).

I searched “raytech faceting machine” on youtube and came up with eleven videos on faceting with it. I would suggest you start by watching a few of them and I think the methods that people use will be self-evident after a while. Look and see who seems to be fast and efficient.

People who get proficient with the Raytech or other platform machines seem to facet very fast. It is an easy machine to cheat in facets with shims under one or another foot or by moving the foot adjustments. The platform on the machine is known for being imprecise and having a good bit of play in it, but this is compensated for by the ability to drift in facets thru the ease of cheating. You may find some info somewhere on modifying the machine to make the platform more accurate. I think I saw something like this somewhere years ago, but I can’t remember where.

As you probably know if you looked at platform and mast machines, there are two basic faceting machine styles. They are quite different. There is a way to attach a depth of cut ohmmeter to the Raytech type machines, but I cannot remember how it is done. As I say, most people just take advantage of the easy inspection and easy cheat features and cut that way. The Raytech head is not easy to set to exact fractional angles as far as I can see.

I would go to the various faceting forums and see what old info I could find. If I were you I would try out a good mast type machine at some point to get an idea of whether the Raytech style is right for you or whether you might like the mast style better. One can cut quite well on a Raytech style machine…I just got 23 stones back from a cutter in Nigeria who uses a Raytech type machine and they were cut superbly. Good luck on your faceting journey! -royjohn

1 Like

Thanks for your response,

YouTube was my first stop, but I was disappointed with the amount/quality of the Raytech-centric content (though I was able to learn a ton from the little I found) compared to mast-style machines. One big exception (regarding quality and amount) is Justin K. Prim who uses a Sri Lankan handpiece style machine. His videos are great, and it appears as though there is a lot of overlap between that machine and the Raytech, but I’m not sure how much…

Thanks again for your input!!

Hi Nick,

Justin has a great reputation in the faceting community and I would think anything he says is pretty reliable. I looked at the Sri Lankan machine and the concept is pretty similar to the Raytech…the Sri Lankan machine has an angle vernier which permits angle setting to a tenth of a degree and I cannot find a photo of the Raytech handpiece that allows me to tell whether that is possible on the Raytech, and the Raytech website is no help on that…I also see a cheater on the Sri Lankan machine and I’m not sure how the Ratech handles that. I suppose it has one, but IDK how accurate.

The main difference I can see between the Raytech and typical mast machine is that unless you can figure out how to attach an ohmmeter to the Raytech, the accuracy is limited by cut-and-look. The advantage of a mast machine with a very accurate depth gauge (retrofitted 0.0001" gauge) or a digital angle gauge accurate to 0.01 degrees is that a lot of the cut-and-look is eliminated. On my XS3 (custom machine no longer available), I can cut to the angle reading and then do one or two cut-and-look steps to refine the meet point. The same would be true for the UltraTec with DAD. On the Raytech, you can pick up and examine a little quicker and easier than on a mast machine, but you will have to do so much more often. If you develop a very good sense of how much to cut without looking, you can get very fast with the Raytech, and I assume there is some ease of cheating by varying your hand pressure that allows you to cheat pretty easily. As I said, those who get used to them love them and evidently are very fast with them. As I also remarked, the Nigerian cutter I work with has a machine that looks like that Sri Lankan one and his work is very good. I guess in the end it depends on what turns your crank. However, you have to bear in mind that very few people have ever made any comparisons…they just start with a machine and then that is what they recommend.

If I were you, I would look into putting an ohmmeter on your machine and then I would get some practice under my belt, as that is the only way to decide whether faceting is for you in the long term and whether you are going to like your machine and prosper with it. Joining a club or getting some hands on lessons with a mentor are the only ways of trying out other machines if you have any interest in that. The Midwest Faceters’ Guild does workshops, and the Middle Tennessee Gem and Mineral Society has a couple of locations where faceting is taught and where you would find machines to try…IDK whether they do any weekend workshops presently or not. There are summer weeklong faceting workshops at the William Holland lapidary school and also at the Wild Acres school…all of these are in the East, and IDK where you are situated. I am sure there are some other possible opportunities out towards the West Coast. Best of luck! -royjohn

1 Like

Congratulations on getting your machine. I’ve had mine for a number of years and I’m very satisfied with it.

- My resource for parts and advice is raytechshaw.com. I’ve gotten new belts from them and theyhelped with putting new brushes in the motor.

- I don’t know about the variety of handpieces, but some of my friends have a machine designed by Glenn Vargas. It’s a similar design and the handpieces are pretty much the same.

- The machine is compact and can be used almost anywhere. I’ve cut stones sitting on a couch with the machine on a coffe table, and I’ve cut stone, standing, with the machine on a high bench in the garage. I currently have the machine at desk level.and work from an office chair.

4, You might want to think about getting the attachment for forming standard shapes. It goes on a post that is located on the front left corner, if you don’t already have one. It’s great for preforming to standars/commercial shapes (round, oval, pear, and marquise), especially cabs.

Good Luck and enjoy , , Max

Thanks for the info!

That Standard Shapes Adapter sounds amazing! Is there a special name for this piece? I asked Rick from Raytech about a table adapter (before I knew you didn’t need one on a Raytech) and he said he had never heard of one. Do you have any pics of it?

I bought a RayTech Shaw machine last year from Pete Brush at Westerngem.com He also sells many parts and has been faceting for decades with it. If you go to his website on the “about us” page, there is a place you can click that says " click here to see how these stones are cut". It is a useful step-by step with pictures. I have made progress with my cutting, but I am still messing up when I get to cutting the stars. And I am just starting to make progress with better polishing techniques. Good luck with this! I know I will be able to master this when I have more time to put in to it as I still work full time.

1 Like

Hi! I Teach all my students on Raytech. They originally were made here in CT. I’m not sure where they are located now but I do know there are suppliers still. They are a faster faceting machine but not as accurate as some if the High end ones like Ultratech etc. I even use the old Lee Machines still. They are great machines still! The hand piece is easy to use ( not as easy as a fixed stand like Lee or Ultra but again it’s faster to make the index changes. I use it to re- facet chipped stones as well because its very easy to use the cheater on. Enjoy! - Mike at Acquire Collectibles Gemological Laboratory

1 Like

Couple of things. I wouldn’t call this a “table adapter”. It came with my machine (purchased over 20 years ago) and fits right on a post located on the left front corner of the machine. You don’t reall need one, but it is very handy for doing preforms.

I’m be happy to send a couple of photos, but not sure if this works

1 Like

Hi Nick,

Someone mentioned Rick . . He helped me out with an arbor assembly replacement part for my RAYTECH. Perhaps he can answer some of your questions. Rick@RayTECHSHAW.com.

Good luck, have fun and God bless!

1 Like